AI ghost kitchen inventory management systems are transforming food delivery services by optimizing operations through artificial intelligence, significantly reducing packaging waste. These solutions automate tasks like inventory tracking and order fulfillment using machine learning algorithms to predict demand patterns, preventing overstocking or understocking and minimizing food spoilage. AI-driven recommendations for eco-friendly packaging materials further promote sustainability while lowering operational costs. Integrating AI technology into food delivery businesses offers strategic advantages for enhanced efficiency and sustainability, making it a game-changer in the quick-paced delivery sector.

In today’s fast-paced food delivery landscape, AI ghost kitchen inventory management systems are revolutionizing operational efficiency. These advanced tools leverage artificial intelligence for real-time tracking and optimization, addressing the pressing issue of packaging waste. By understanding the benefits of AI in inventory control and waste reduction, businesses can make informed decisions to enhance sustainability. This article explores the integration of AI packaging waste reduction tools into food delivery operations, offering a roadmap to navigate this transformative technology.

- Understanding AI Ghost Kitchen Inventory Management Systems

- Benefits of Implementing AI for Packaging Waste Reduction

- Integrating AI Tools into Your Food Delivery Business

Understanding AI Ghost Kitchen Inventory Management Systems

AI ghost kitchen inventory management systems are transforming the way food delivery services optimize their operations. These innovative solutions leverage artificial intelligence to streamline the complex process of managing ingredients, packaging, and waste in high-volume, temporary cooking spaces known as ghost kitchens. By automating tasks such as inventory tracking, order fulfillment, and supply chain optimization, AI tools can significantly reduce packaging waste, a major environmental concern in the food industry.

Through machine learning algorithms, these systems analyze historical data, predict demand patterns, and automatically adjust ingredient stocks accordingly. This precision prevents overstocking or understocking, minimizing food spoilage and the subsequent waste that often results from it. Furthermore, AI-driven recommendations for packaging materials and sizes help delivery platforms adopt eco-friendly practices, contributing to a more sustainable future while also reducing operational costs.

Benefits of Implementing AI for Packaging Waste Reduction

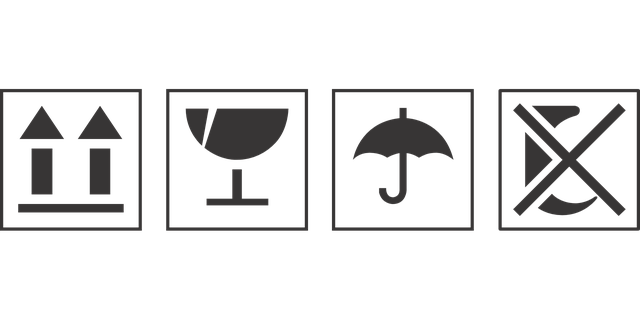

Implementing AI in ghost kitchen inventory management offers significant advantages when it comes to reducing packaging waste. These advanced tools can analyze consumption patterns and predict demand, ensuring that only the necessary amount of packaging materials are used. By automating this process, kitchens can minimize excess waste generation, especially from single-use items, contributing to a more sustainable practice.

AI algorithms can also optimize packaging design, suggesting eco-friendly alternatives and streamlining the entire process. This not only reduces waste but also aligns with consumer expectations for environmentally conscious brands. With AI’s precision and efficiency, ghost kitchens can take a proactive step towards sustainability, making their operations more cost-effective and appealing to ecologically mindful customers.

Integrating AI Tools into Your Food Delivery Business

Integrating AI technology into your food delivery business is a strategic move that can significantly enhance efficiency and sustainability, especially in ghost kitchens where inventory management is key. AI packaging waste reduction tools are emerging as game-changers, offering solutions to streamline operations and minimize environmental impact. These intelligent systems can analyze vast amounts of data to predict demand, optimize stock levels, and reduce food waste—a common challenge in the quick-paced delivery sector.

By employing AI algorithms, ghost kitchen managers can gain real-time insights into inventory, enabling them to make informed decisions. This precision allows for efficient packaging, ensuring that only the necessary amounts of ingredients are used, thereby cutting down on packaging waste and associated costs. With AI at the helm, your business can foster a more sustainable practice while maintaining high operational standards, appealing to environmentally conscious consumers.

AI ghost kitchen inventory management systems offer a revolutionary approach to optimizing food delivery operations, particularly in addressing the pressing issue of packaging waste. By implementing these advanced tools, businesses can streamline their processes, reduce waste, and contribute to a more sustainable future. The benefits are clear: improved efficiency, cost savings, and a positive environmental impact. Integrating AI into your food delivery strategy is not just a trend; it’s a smart step towards a greener, more efficient industry. With the right AI packaging waste reduction tools, ghost kitchens can excel in both operational excellence and eco-friendliness.